1. X-ray focussing

Telescope optics at soft X-ray bands employ grazing incidence reflection from metal surfaces. The refractive index of metals in X-rays is slightly less than one so it is possible to get a total external reflection at a vacuum-metal interface if the X-rays are incident nearly parallel to the metal surface. The limiting angle of grazing incidence lies between a few degrees at ~0.1 keV to a few arcminutes at ~10 keV.

Sections of paraboloidal surfaces, far from their apex, can be configured to focus soft X-rays via grazing incidence. However, this arrangement strongly violates the Abbe sine condition and the images in the focal plane seriously suffer from Coma. This can be remedied by including a second reflection, for example from a hyperboloidal surface, as displayed below. This is known as the Wolter-I optical arrangement, and has been adopted in most of the focussing X-ray telescopes flown to date.

Wolter-I imaging principle

As only a degree or so in angle from each surface is in effective use, it is possible to nest such surfaces within one another, with a common focus, to increase the collecting area.

Example of Nesting

2. Foil Optics

While the Wolter-I optics provides excellent imaging quality, the production and maintenance of the accurate paraboloidal-hyperboloidal surfaces is very expensive and require thick, heavy mirror substrate. This also limits the number of nested surfaces that can be accommodated to just a few.

An alternative that has emerged over the past decade is to approximate the paraboloid and the hyperboloid by conical surfaces that are tangent to them. This sacrifices the image quality somewhat, the resulting point spread function being of order an arcminute. However, one can produce these conical surfaces using thin, lightweight foils, and nest a large number of such foils to achieve a large collecting area. The SXT optics on ASTROSAT has adopted this design. Two separate mirror blocks are needed, one to replace the parabolic section (called the 1-alpha section) and the other to replace the hyperbolic one (called the 3-alpha section). These two blocks are then accurately aligned into the final mirror assembly.

3. ASTROSAT SXT mirrors

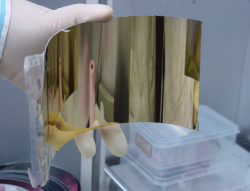

ASTROSAT SXT mirrors are made of 10 cm long shaped conical shells of 0.2 mm thick Aluminium. Each foil is coated with 20-50 micron thick epoxy and on it is deposited a 1400 Angstrom thick layer of Gold which acts as

the reflecting surface. Each shell is made of four quadrant segments, and there are 41 such nested shells in both 1-alpha and 3-alpha sections, thus requiring a total of 41x8=328 foils. Some of the basic parameters of the mirror assembly are:

Focal Length : 2000 mm

Max. foil radius : 130 mm

Min. foil radius : 65 mm

Reflector length : 100 mm

Min. reflector spacing : 0.5 mm

SXT foil mounting arrangement (detail)

A schematic of the ASTROSAT SXT reflector

assembly. The upper half consists of the

1-alpha section foil mirrors and the lower

half the 3-alpha section.

A shaped and gold coated foil segment

SXT foil optics assembled for testing

Measured reflectivity of gold-coated

foils at 8 keV as a function of

angle of grazing incidence

Top view of the 1-alpha section